The fastest way to grow your business with the leading Plastic Recycling Check out our options and features included.

Plastic Recycling ReProcess Reuse the materials into useful products.

The goal of recycling plastic is to reduce high rates of plastic pollution while putting less pressure on virgin materials to produce brand new plastic products.

Waste Plastics

Waste Plastics

Crushed Flakes

Crushed Flakes

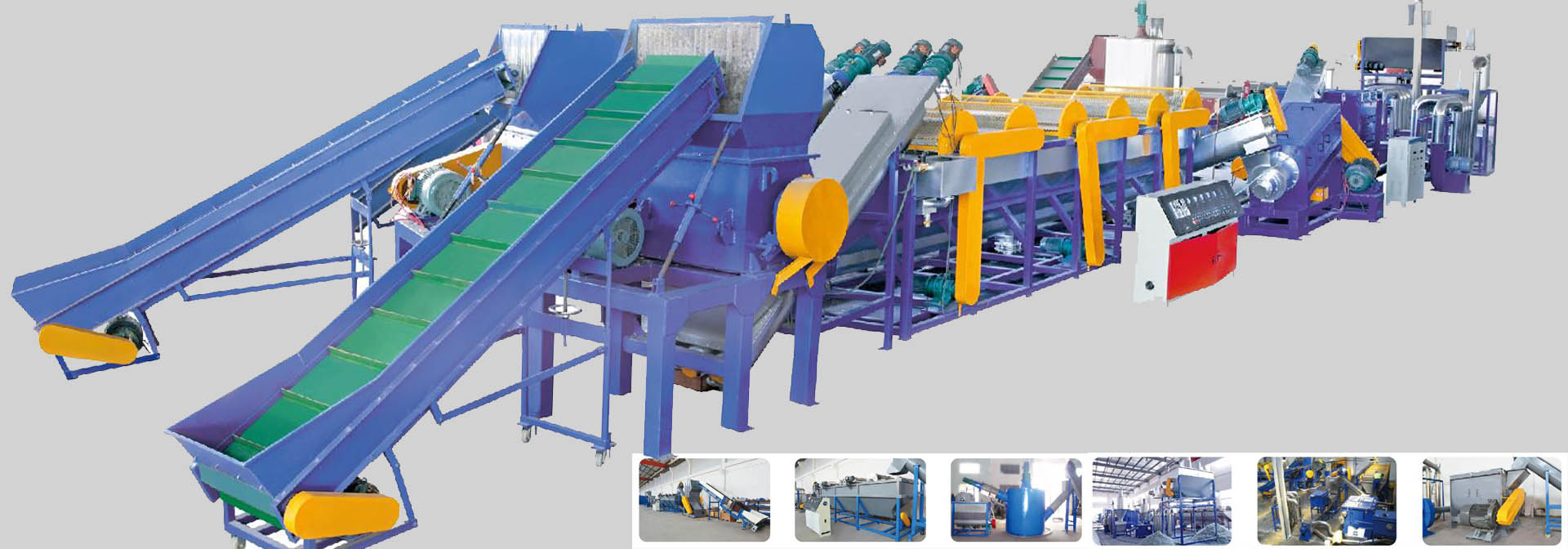

Washing Line

Washing Line

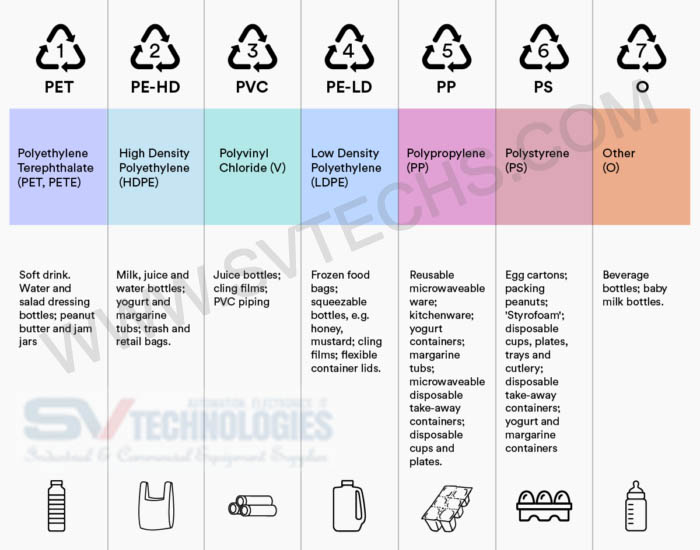

Types of Recycling

PET Recycling

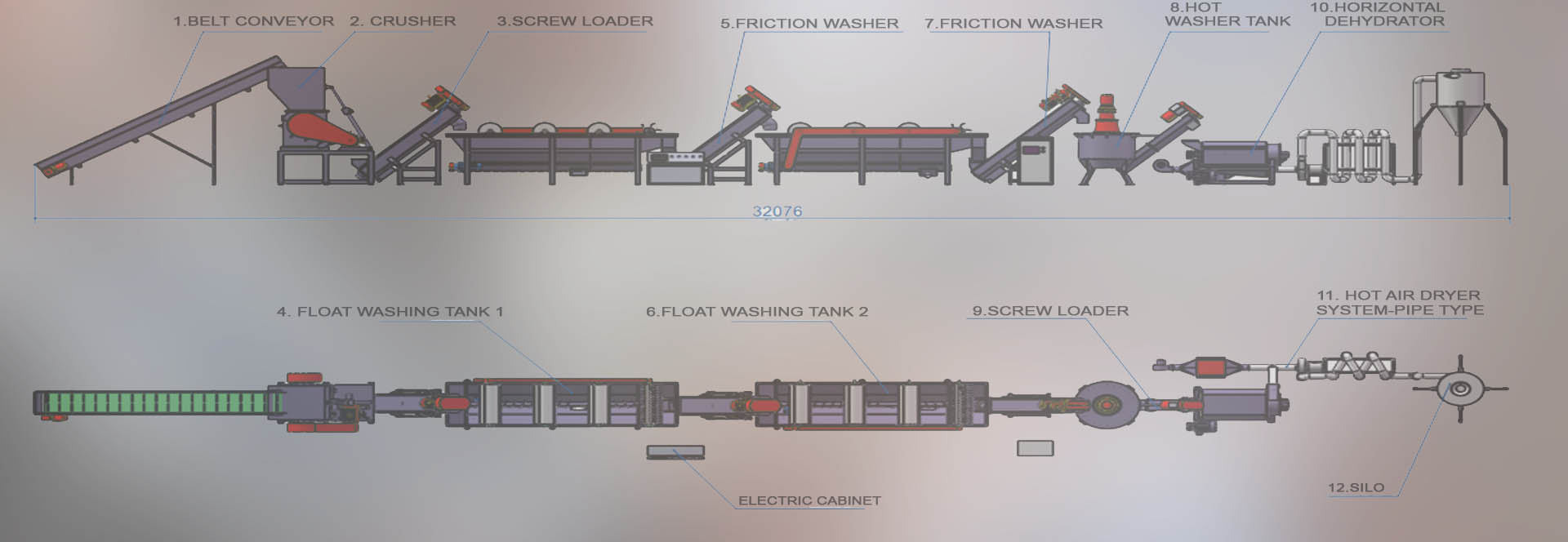

The complete production line mainly includes : sorting table—Belt conveyor–label removing machine–Belt conveyor–crusher–screw conveyor–washing tank–Stuff-fetching machine–hot water washing tank–screw conveyor–frictional machine–floating washing tank–Stuff-fetching machine–dehydrator machine–stock bin and packing

PS/ABS Recycling

This PS/ABS Washing Recycling machine adopt the advanced technology, with many steps to separate out the impurities. And the line with the on-line chemical recycling system which can guarantee the separating effective and save the running cost;

PE/PP Film, Woven Bags Recycling

special crusher,grinder machine for the film, sack, with special blades design and the mesh design; so the output material is samller size but capacity is higher; It helps washed material more cleaning; And save labor cost and save energy; You may choose shredder machine to reduction the material size, its according to your requirement;

HDPE Recycling

HDPE bottle recycle is a very important part in plastic recycling area, this recycling washing equipment is suit for below raw material recycle:After using our washing line ,it can be go to extruder, injection ,then make the products which you needed.

and more...

Belt conveyer → Rolling separator →Manual pick table → Metal separator → Belt conveyer → Crusher → Label Separator → Hot washer 1 → Friction washing machine → Hot washer 2 → High-speed friction washing machine → Rinsing tank → Spray washing→ Dewatering machine → Blower dryness system → Storage hopper → Finished product packing

Belt conveyor → Crusher → High-speed friction&washing machine → Film Rinsing Machine → Screw Feeder → Horizontal Spin-drier → Air Drying System → Cyclone storage

Belt Conveyor → Film Feeding → Compactor → Film Compactor → Single Screw Extruder → Venting System → Hydralic Screen Changer → Non-stop changing the net → Water-ring Cutter → Horizontal or Vertical → Spin-Dryer.

Processing Capacity as 300-500Kg/h

The Crushing,washing & drying line can easily wash waste plastic products from begining to finished products. Waste and dirty agricultural films and waste packing material or hard plastic can be treated step by step by this facility. Concise and effective design of the production line makes the production line rather popular both at home. The equipment certified as CE for quality,safety and reliable.

Processing Capacity as 300-1000Kg/h.

Recycling is an important step towards improving the environment and reducing carbon footprints. Plastic PET Washing Line is designed to recycle different kinds of dirty bottles, like oil bottle, Soft drinks bottle,ect . After washing , usually the material will go for further process-pelletizing and then the granule can be used to make different kinds of plastic products

Processing Capacity as 300-500Kg/h.

This system has smart modular design aiming at agricultural film, industrial packaging film, bag, blow molding packaging bottle / box, injection and electronic waste recycling. Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove ferrous and nonferrous metals, sand, oil, glue, paper label and many other different contaminants efficiently. You can get a different module combinations design from us according to your requirements and material's condition. In range of different raw materials, We provides 300-500 kg/h economy and high-level production lines with different configurations.