Plasma/Flame Cutting Products

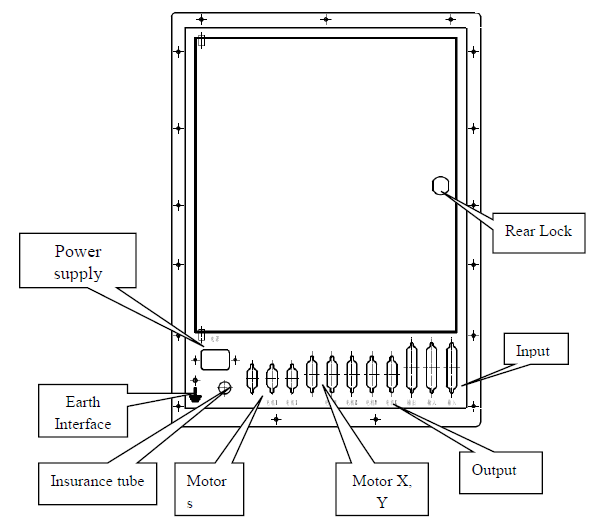

TM300A Plasma Cutting Controller

* This is a Plasma/Flame Intergrate CNC Cutting Controller.

* Based on ARM9+FPGA high performance processor .Max speed is 30m/min.

* This controller has a strong anti-interference capacity and can compatiable with

most of Plasma power supply .

* TM300A support Fastcam,Art-cam etc CNC post softwares.

1) ARM9 high-speed Microprocessor and super large programmable FPGA

2) Real time multitask control technology and hardware interpolation technology

3) 10.4 Inch real color display screen, Friendly and easily operation interface

4) Supporting multi language display

5) All Photovoltaic isolation control, super large anti-interface ability

6) Large storage space process file: 64M, demand complicated/large program running and processing

7) Plasma /flame controller can control 2 step/servo motor , Also support 2 extra axis synchronization for

gantry type machine

8) Graphic library: 24 graphs, convenient for customer fast cutting

Graphic real time modification function, supporting figure rotation, correction and mirror ,array etc

9) Support preheating, perforating, automatic corner acceleration and deceleration

10) Break point recovery function

11) USB communication , directly read file by U disk

12) support most of CAM software ,like STARCAM ,IBE , FASTCAM

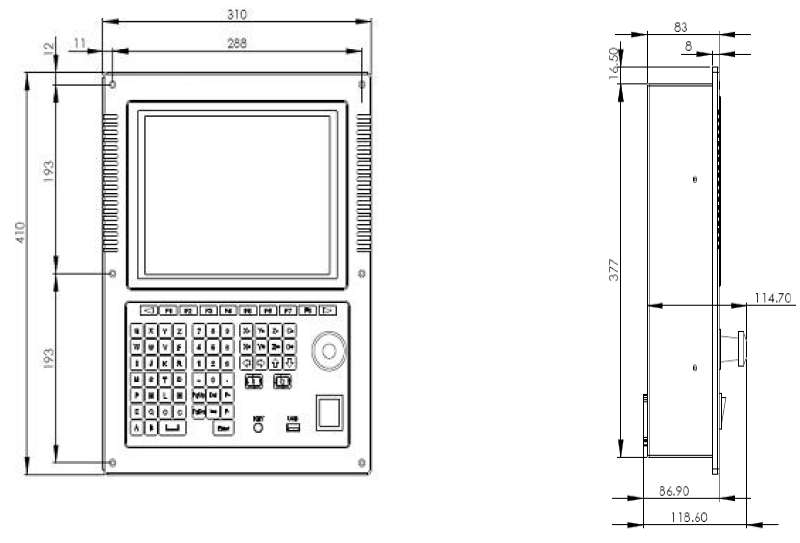

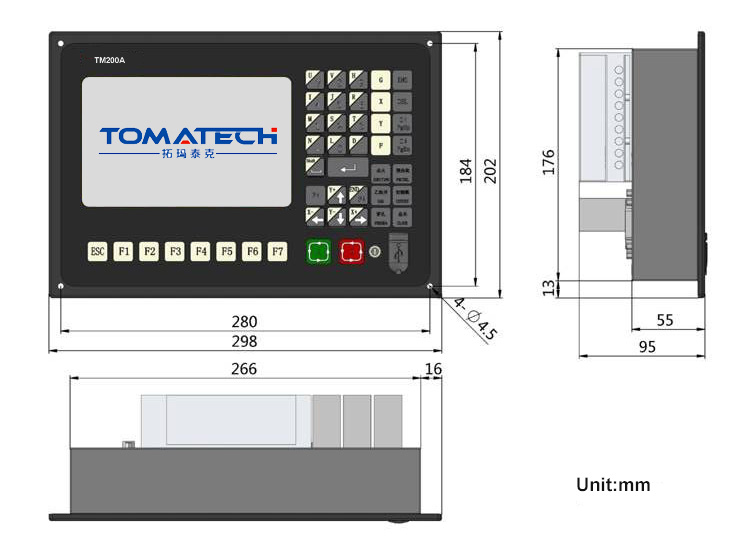

Plasma Cuting Contoller- TM200A

* This is a Plasma/Flame Intergrate CNC Cutting Controller.

* Based on ARM9+FPGA high performance processor .Max speed is 30m/min.

* This controller has a strong anti-interference capacity and can compatiable with

most of Plasma power supply .

* TM200A support Fastcam,Art-cam etc CNC post softwares.

1) ARM9 high-speed Microprocessor and super large programmable FPGA

2) Real time multitask control technology and hardware interpolation technology

3) 7 Inch real color display screen, Friendly and easily operation interface

4) Supporting multi language display

5) All Photovoltaic isolation control, super large anti-interface ability

6) Large storage space process file: 64M, demand complicated/large program running and processing

7) Plasma /flame controller can control 2 step/servo motor , Also support 2 extra axis synchronization for

gantry type machine

8) Graphic library: 24 graphs, convenient for customer fast cutting :-

Graphic real time modification function, supporting figure rotation, correction and mirror ,array etc

9) Support preheating, perforating, automatic corner acceleration and deceleration

10) Break point recovery function

11) USB communication , directly read file by U disk

12) support most of CAM software ,like STARCAM ,IBE , FASTCAM

Portable CNC Plasma Cutting Controller- SF2100S

High anti interference 3 axis CNC Plasma cutting machine controller

Power Request : AC220V 50/60Hz

Power Dissipation : <10W

Work Temperature : 0°C-60°C

Storage Temperature : -20°C-80°C

Work Humidity : 20%-95%

Storage Humidity : 0%-95%

CNC Oxygen flame Plasma Cutting Controller-SF2300S

SF2300S Original cutting system support THC CNC Plasma cutting machine

Oxygen flame Plasma Cutting machine controller for CNC gantry machinery

4 Axis Turning Controller-2000 Series

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed tempus nibh sed elimttis adipiscing. Fusce in hendrerit purus.

Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fusce sagittis, massa fringilla consequat blandit, mauris ligula porta nisi, non tristique enim sapien vel nisl. Suspendisse vestibulum lobortis dapibus.

Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae; Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fusce sagittis, massa fringilla consequat blandit, mauris ligula porta nisi, non tristique enim sapien vel nisl. Suspendisse vestibulum lobortis dapibus. Vestibulum ante ipsum primis in faucibus orci luctus et ultrices posuere cubilia Curae;

| Size: | Unique |

|---|---|

| Colors | Red, Blue |

| Material | 100% Leather |

Add a review

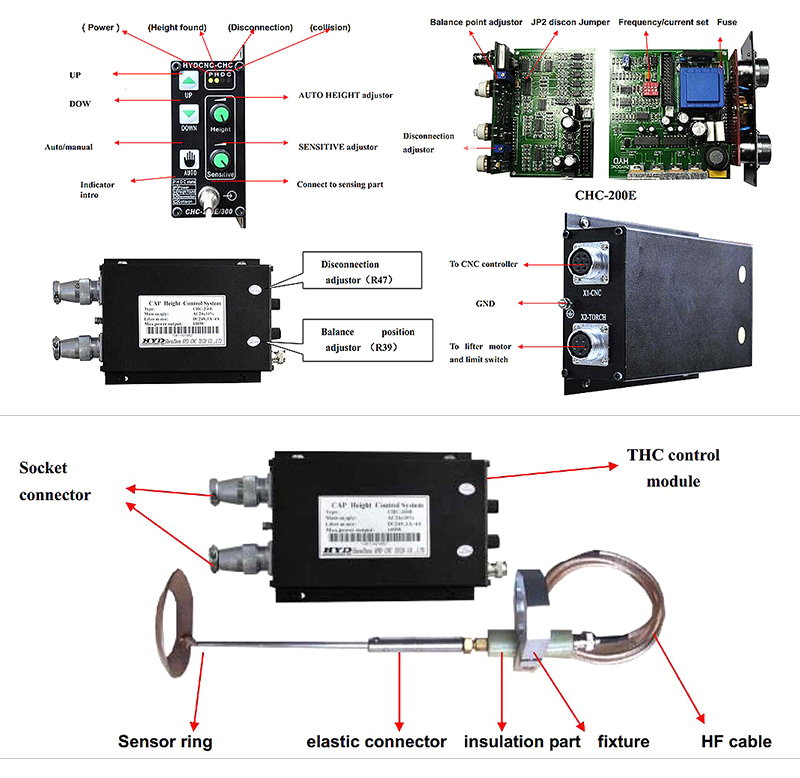

Capacitive Torch Height Controller- CHC200

Torch Height Controller for CO2/YAG laser and Plasma /Flame Cutting Machine.

It is the newest cap THC we designed for flame cutting, stand alone type, support any cnc controller, widely used by almost China manufacturers, include Koike China, Messer China, AMG...etc.

It works with AC24V or DC24V, support DC 24V motor below 100A.

Advantages:

- Comparing to CHC-200D, CHC-200F has new features as follow,

- 1, Increased more indicators to shows different states of THC.

- 2, Output of collision-alarm, which is optical isolation output from THC, can be sent to CNC’s Alarm input to freeze machine’s move. This signal is effective on both manual/auto mode. The max output is 200mA, capable to drive most relays.

- 3, Anti-collision function. On manual/auto mode, when metal or low-conductive item like hand touches sensor ring, THC would send out collision signal and lift torch up until no collision exist.

- 4, When HF cable is disconnected or weakly connected, it would be indicated on the disconnection indicator. So after installation of HF cable, just shake the HF cable, the connection will be showed by the indicator.

- 5, Sensitive and Accuracy is increased 100%.

- 6, CHC200E uses digital logic control circuit for logic control, greatly improved anti-interference performance.

| Power supply: | AC24V +/- 10%, 50Hz/60Hz; |

| DC motor used on lifter: | DC24V; |

| Output current: | 1A-4A, max: 100W |

| Work temperature: | THC-10~60 degrees; HF cable: -10~ 200 degrees; Sensor parts: -10~350 degrees |

| Accuracy: | +/- 0.1mm (matters with lifter design); |

| Auto height range: from cutting material surface 1mm-20mm | |

| HF-cable: | 200mm~1300mm |

| Product size as figure L*W*H: | 176mm * 105mm * 50mm |

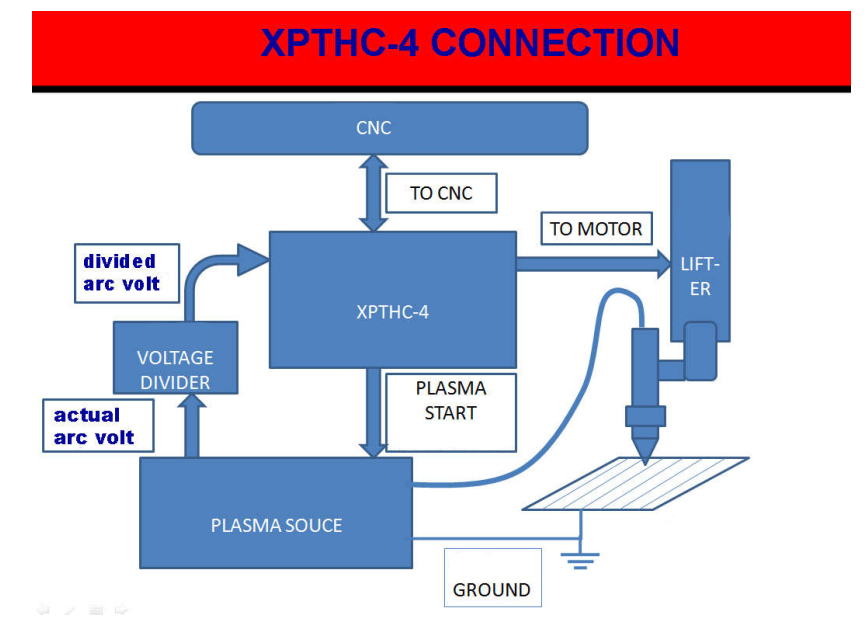

Arc THC for Plasma Cutting Machine- XPTHC-4H

Stand Alone Arc Voltage Torch Height Controller,XPTHC-4H is updated model for XPTHC-4, it adds two potentiometers on panel, used more conveniently when set voltage and IHS height. Other functions are same as before.

XPTHC-4 is the newest design THC, special for portable CNC cutting machine and small bench type machine, with 32 ARM processors, and analogous circuit height control together.

Feature:

- 1, installation: user could install the THC’s operation panel on the work interface, or install it at the convenient operation place. Install the main body at a suitable station.

- 2, height controller: could change the auto cutting height at any time

- 3, two modes of the setting arc volt:

- A, Setting arc volt mode: set the setting arc volt on the operation panel, let the THC work on the setting arc volt status. It’s the traditional work way.

- B, sampling arc volt is the setting arc volt: when the THC control the torch finish the HIS and plasma start, and CNC controller open the AUTO signal to THC, and THC will test the arc value as the setting arc when at beginning the AUTO status. It’s suitable for some small plasma.

- 4, High Sensitivity: adjusting the THC’s sensitivity, could realize the arc volt change 1V, the arc voltage output will change 1.5V~4V, and don’t occur the vibration. So the lifter’s start voltage is closed related to the THC’s sensitivity, Our lifter’s start voltage is 1.5V ~2V.

- 5, Good stable: XPTHC-4 has 5 sets isolation power inside, to realize the I/O isolation; sampling arc volt isolation; drive isolation; and control isolation.

Specification:

- Working voltage: AC24V+10%, 50Hz/60Hz or DC24V±20%;

- Adapter motor: DC24V DC motor, up to 25W;

- Drive mode: PWM (pulse width modulation mode);

- Output current: 0.1A-1A;

- Working temperature: height adjuster -10∽60°C;

- Initial positioning mode: switch initial positioning & proximity switch initial positioning;

- Run transmission mode: Detect arc voltage enable output, 200mA optocoupler OC gate output.

- Partial voltage ratio: external 50:1 non-isolated partial pressure; internal 1:1 isolation voltage divider.

- Accuracy: ±1V∽±3V, related to the user's motor and the structure of the lifter;

- Adaptable torch lifting speed: 1 m / min ∽ 3 m / min (contact the supplier for this speed);

- Set the arc voltage range: 50V ∽ 250V,

- Overload protection mode: PWM speed regulation, current feedback;

- Maximum cutting tracking test speed: 12000mm/min (related to the motor starting voltage and speed of the user's lifting body and sensitivity setting).

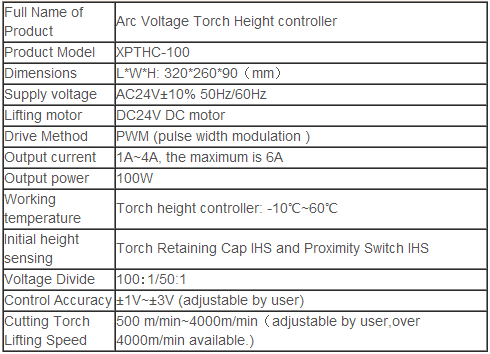

Stand Alone Arc Voltage THC-XPTHC100-III

1. Newest plasma torch height control

2. Support all CNC controllers, plasma cutters on market.

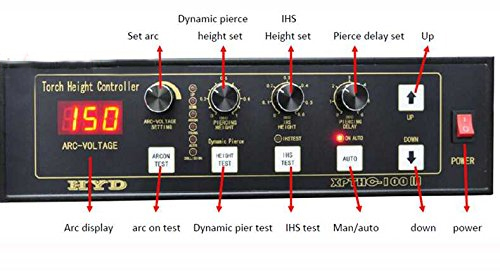

New feartures

1. Better operation, new operation panel design.

2. Added Dynamic Pierce, protect torch retaining cap.

3. Better anti-interference design.

4. Better work stability.

New Feartures

- 1. Better operation, new operation panel design.

- 2. Added Dynamic Pierce, protect torch retaining cap.

- 3. Better anti-interference design.

- 4. Better work stability.

- A. Auto Initial Height Sensing(IHS)

Torch Retaining Cap IHS and Proximity Switch IHS (NPN and PNP), Proximity Switch IHS is backup for Torch Retaining Cap IHS for cutting dirty/rusty workpiece, needing the Anti-Collision Fixture designed by HYD (optional ). - B. Torch Anti-Collision Function

We designed Touch-Up circuit for Anti-Collision Function. No matter it is on Auto Control Model or Manual Control Model, when torch head touches the workpiece, THC would automatically lift torch up to IHS height. So with XPTHC-100, even in Manual Control Model, user doesn’t need to worry about torch head crashing. - C. Freeze Auto Height Control on Corner Signal

XPTHC-100 can recognize Corner Signal from CNC and freeze Auto Control Model on receiving this signal, protect torch on voltage spikes (Corner Turning, Kerf Crossing) effectively. - D. Set Pierce Time

- Set the Button (Set PIERE) to set Pierce Time.

- E. Manual Operation

- Many functions can be Manually operated on THC Operation Panel such as setting Auto/Manual, Up and Down, testing of IHS and Arc Start….etc

- F. Arc Voltage Divide

Isolation Voltage Divide detection, the Voltage Divide ratio is 100:1/50:1. And XPTHC-100 supports different HF plasma.

XPTHC height controller is designed for flame, plasma cutting machine development and design of the torch height automatic control device. Automatic height adjustment device combines the capacitor detection, arc voltage detection, stepper motor height control, high precision screw linear guide mechanical transmission of various parts, the use of micro-single-chip computer control, in the automatic calibration function with the direct display torch height. automatic height adjustment device has a very good hardware reliability. Shell selected sealed anti-interference waterproof and moisture-proof aluminum box design, especially for flame cutting, plasma cutting high temperature, high electromagnetic interference harsh environment. Simple interface control, suitable for all flame cutting, plasma cutting CNC system can also be used alone. Height controller is easy to use, easy debugging, low price, adhering to the characteristics of Staud products has always been "imported performance, domestic prices." Welding and cutting equipment manufacturers is the ideal matching products.

Technical Data

Model:XPTHC-100

Dimensions(L*W*H):320*260*90mm

Supply voltage:AC24V±10% 50Hz/60Hz

Lifting motor:DC24V DC motor

Drive Method:PWM (pulse width modulation)

Output current:1A~4A, the maximum is 6A

Output power:100W

Working temperature:(torch height controller)-10℃~60℃

Initial height sensing:Torch Retaining Cap IHS and Proximity Switch IHS

Voltage divide ratio: 100:1

Accuracy:±1V~±3V (adjustable by user)

Lifting Speed:500 m/min~4000m/min adjustable by user,over 4000m/min available.)

Remote Controller for CNC Flame Plasma Cutting machine

Suitable for SF-2100S/SF-2300S/SF-2100C flame plasma cutting

1. Full operation button function interface, easy to adjust cutting state before and after processing.

2. Over 20 meters of control distance, anti-interference co-frequency encryption.

3. Adopt 2.4GHz RF transmission technology.

4. 23 function keys start, pause, rewind, perforation, gas, total off, forward, arc start, height increase, torch lift, acceleration and deceleration, slow speed / high speed, 8 direction keys

Plasma Torch Lifter

MODELS

- TAC-100-DC24V-G - 100MM

- TAC-130-DC24V-G - 130MM

- TAC-150-DC24V-G - 150MM

- TAC-200-DC24V-G - 200MM

The flame/plasma cutting machine Z-axis torch lifter is driven by DC gear motor to lift the torch up & down. The most important part of the device, which is to keep the machine's cutting accuracy and to support plasma arc positioning function, is equipped with NPN proximity switches. The lifter's machenical movement part is made of Taiwan TBI ballscrew or 304 stainless steel, standard linear shaft(SFC) & linear slider on the ends; torch clamper/holder is made of bearing steel, and fasterned by linear sliders, which is to ensure the lifter movement's stability & verticality. Convenient to install, work simple, improving the work efficiency.

TAC-100-DC24V-G

Stroke: 100mm.

Working Speed: about 1600mm/min.

Torch clamp included(torch size: 12-38mm)

Movement shaft material: 25mm TBI-1605 ball screw.

Aluminum box: 10mm body & 8mm covers, primary molding, unique integration aluminum alloy, to avoid the jitter arc breaking problem during the cutting process.

Built-in plasma arc positioning function (default shipping model: NO contact 2 wires)

Working Voltage: DC24V-20W.

Net weight: about 3kg.

Loading ability: 3.0 kg.

Aviation Plug Wiring

Pin 1--D+ (Motor +)

Pin 2--D- (Motor -)

Pin 3--Zero(Initial positioning Output)

Pin 4--Com(Initial positioning Output)

TAC-130-DC24V-G

Stroke: 130mm.

Working Speed: about 2000mm/min.

Torch clamp included(torch size: 12-38mm)

Movement shaft material: 25mm TBI-1605 ball screw.

Aluminum box: 10mm body & 8mm covers, primary molding, unique integration aluminum alloy, to avoid the jitter arc breaking problem during the cutting process.

Built-in plasma arc positioning function (default shipping model: NO contact 2 wires)

Working Voltage: DC24V-20W.

Net weight: about 3kg.

Loading ability: 10.0 kg.

Aviation Plug Wiring

Pin 1--D+ (Motor +)

Pin 2--D- (Motor -)

Pin 3--Zero(Initial positioning Output)

Pin 4--Com(Initial positioning Output)

TAC-150-DC24V-G

Stroke: 150mm.

Working Speed: about 2000mm/min.

Torch clamp included(torch size: 12-38mm)

Movement shaft material: 25mm TBI-1605 ball screw.

Aluminum box: 10mm body & 8mm covers, primary molding, unique integration aluminum alloy, to avoid the jitter arc breaking problem during the cutting process.

Built-in plasma arc positioning function (default shipping model: NO contact 2 wires)

Working Voltage: DC24V-20W.

Net weight: about 5kg.

Loading ability: 10.0 kg.

Aviation Plug Wiring

Pin 1--D+ (Motor +)

Pin 2--D- (Motor -)

Pin 3--Zero(Initial positioning Output)

Pin 4--Com(Initial positioning Output)

TAC-200-DC24V-G

Stroke: 200mm.

Working Speed: about 2000mm/min.

Torch clamp included(torch size: 12-38mm)

Movement shaft material: 25mm TBI-1605 ball screw.

Aluminum box: 10mm body & 8mm covers, primary molding, unique integration aluminum alloy, to avoid the jitter arc breaking problem during the cutting process.

Built-in plasma arc positioning function (default shipping model: NO contact 2 wires)

Working Voltage: DC24V-20W.

Net weight: about 6.5kg.

Loading ability: 10.0 kg.

Aviation Plug Wiring

Pin 1--D+ (Motor +)

Pin 2--D- (Motor -)

Pin 3--Zero(Initial positioning Output)

Pin 4--Com(Initial positioning Output)

High Speed CNC Plasma Power Source

MODELS

- LGK-70IGBT

- LGK-105IGBT

- LGK-120IGBT

- LGJ-160IGBT

- LGK-200IGBT

- LGK-300IGBT

- LGK-400IGBT

- MSW-10L

LGK series inverter type air plasma cutting machine is new design of metal processing equipment,

Insulated gate high power transistor IGBT and pulse width modulation (PWM) soft switching technology are used to design and manufacture.

The cutting machine can cut all metal items, especially suitable for "flame cutting", It can not achieve high alloy steel and non-ferrous metals.

The series of power source have reasonable static and external characteristics, and also have good dynamic characteristics,

With high frequency arc starting function .Widely used in all kinds of machine manufacturing industry.

Main Features

The arc energy is highly concentrated, with good stability and strong cutting force

Cutting speed (3-5 times of gas cutting)

Cutting costs are low

Incision stenosis. Clean and tidy; close to vertical.

Small deformation of workpiece

The cutting current is adjustable continuously

Easy arc setting

The operation is very convenient

Light weight, small size, easy to move

High efficiency, high power factor, it is a kind of energy saving equipment.

Low noise and strong adaptability

Has two functions of self-locking and non self locking, adapt to the length of slot without

requirement, can reduce the labor intensity of workers.

Easy to form cutting equipment

| Model | LGK-70IGBT | LGK-105IGBT | LGK-120IGBT | LGK-160IGBT | LGK-200IGBT | LGK-300IGBT | LGK-400IGBT |

| Rated input voltage | 3~380V/50HZ | ||||||

| Rated input capacity | 15.6KVA | 17.8KVA | 22.4KVA | 32.2KVA | 46.5KVA | 65.4KVA | |

| Rated Output current | 70A | 105A | 120A | 160A | 200A | 300A | |

| Rated output voltage | 100V | 120V | 128V | 144V | 160V | 200V | |

| Rated load sustainability | 100% | 100% | 100% | 100% | 100% | 100% | |

| No-load voltage | 300VDC | 300VDC | 300VDC | 315VDC | 315VDC | 380VDC | |

| Regulating rangeof current | 30~70A | 30~150A | 30~120A | 30~160A | 30~200A | 30~300A | |

| High quality cuttingthickness | 0.3-12mm | 0.3-16mm | 0.3-20mm | 0.3-25mm | 1-35mm | 1-45mm | |

| Maximum cuttingthickness | 20mm | 25mm | 30mm | 35mm | 45mm | 55mm | |

| Use of plasma gas | compressed air | compressed air | compressed air | compressed air | compressed air | compressed air | |

| Working gas pressure | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | |

| The cooling method of cutting torch | air-cooled | air-cooled | air-cooled | air-cooled/ water-cooling | air-cooled/ water-cooling | air-cooled/ water-cooling | |

| Arc ignition mode | Non contact mode | ||||||

| Insulation grade | F | ||||||

| Shell protection grade | |||||||

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae, gravida pellentesque urna varius vitae.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra odio, gravida urna varius vitae, gravida pellentesque urna varius vitae.